One edge of each folded leaf is tacked with thread to a thin metal dowel and sewn through an accordion-pleated spine. The intaglio surface was divided into areas corresponding to the cantilever regions and between implants (n442) and was assessed for shape (concave or convex) and biofilm index (0 to 3). There are sixteen books and four artist proofs in the edition" - Colophon. The 56 prostheses supported by 388 implants had been in place for an average of 5.5 years (range 1-14 years). Whether seating a crown, partial framework or locating occlusal contacts let Quickcheck help you achieve the perfect fit every time. Garamond type set by Michael and Winifred Bixler and printed by Brad Benedict, Blacks Corner Letterpress. Quickcheck Indicator Spray allows technicians to accurately pin point unwanted contact points and high spots on all dental restorations. Comparison of Intaglio Surface Trueness of Interim Dental Crowns Fabricated with SLA 3D Printing, DLP 3D Printing, and Milling Technologies. Do local business owners recommend iNtaglio Dental Laboratory Incorporated Visit this page to learn about the business and what locals in Elk Grove Village. Digital images printed onto the intaglio prints by Chris Tague at the Experimental Printmaking Institute at Lafayette College. Intaglio plates by Kumi Korf, printed by Christa Wolf at Rikka Press, Ithaca, NY, on Copperplate Hahnemuhle paper. "Calligraphy on the title page by Kumi Korf. The intaglio surface trueness is an essential aspect in the clinical performance of CRDPs.Īrtificial saliva CAD/CAM Complete denture prosthesis Complete removable dental prosthesis Dental materials Injection-molding PMMA resin Trueness.Text and the original video stills by Mario Korf, a freediver/hunter-gatherer living on the Pacific Coast in California" - Colophon. Additional research is warranted on material-related aspects, cost-effectiveness, clinical performance, patient-centered outcomes, as well as other CAD/CAM techniques for CRDP fabrication.

In this in vitro study, the trueness of the intaglio surface of all three investigated techniques seems to remain within a clinically acceptable range. However, for all three techniques, 80 % of all deviations of the complete intaglio surface after incubation in saliva were below 0.1 mm. Get Intaglio Dental Laboratorys () location in Illinois United States, revenue, industry, competitors, technographics and.

INTAGLIO DENTAL SOFTWARE

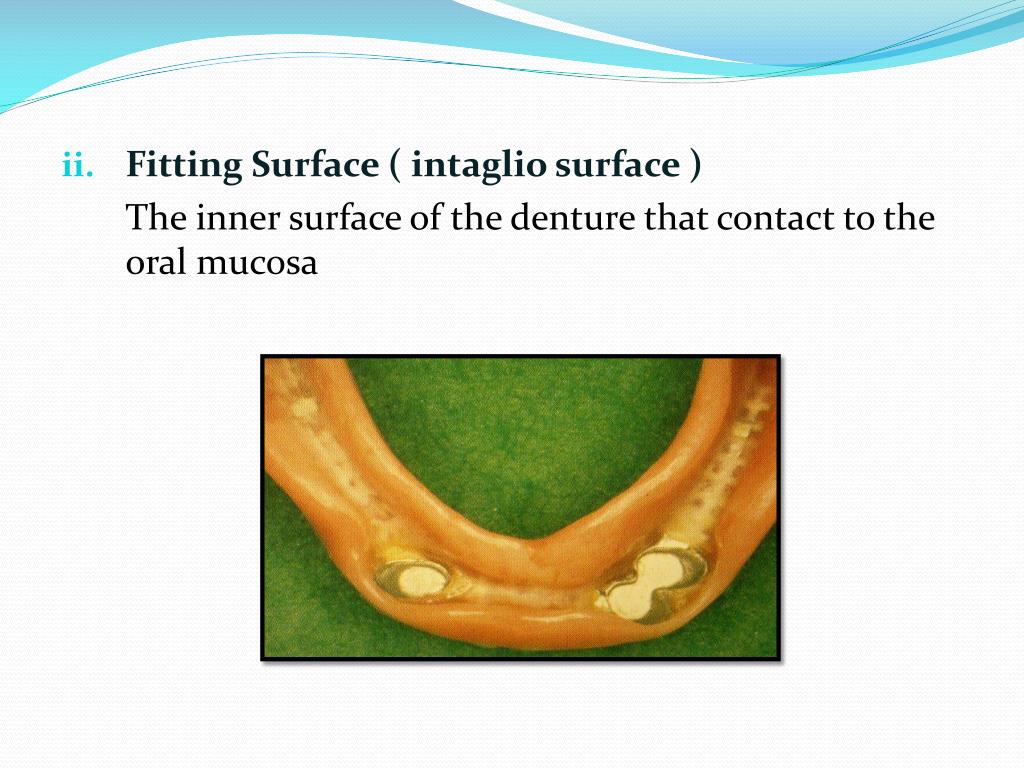

The alignment and 3D comparison of CRM and CTM were performed based on the intaglio surface using a 3D inspection software program (Geomagic Control X). The 80-20 % /2 median quantile of the CAD/CAM group demonstrated the highest variability of individual readings, probably due to the size of the milling instrument. The fabricated interim dental crowns were obtained via 3D modeling of the intaglio surface using a laboratory scanner and designated as CAD test models (CTMs). After incubation, only the conventional CRDPs showed a significant improvement in trueness of the entire intaglio surface (p = 0.0044), but improved trueness was confirmed for all three techniques in most individual regions of interest. Non-parametric tests were used with a level of significance set at p < 0.05.Īt baseline, there was no difference in the trueness of the total intaglio surfaces between the groups. over the world teaching not only his dental skills but also life skills. The trueness of the entire intaglio surface along with five specific regions of interest (vestibular-flange, palate, tuberosities, alveolar crest, and post-dam areas) was compared. PMMA used to transfer information such as esthetics, the intaglio surface. Thirty-three CRDPs were fabricated by three different manufacturing techniques (group CAD/CAM (AvaDent™): n = 11 group injection molding (Ivocap™): n = 11 group flask-pack-press: n = 11) using a single master reference model and incubated in artificial saliva for 21 days. This study aimed to compare the trueness of one type of CAD/CAM milled complete removable dental prostheses (CRDPs) with injection-molding and conventionally manufactured CRDPs.

0 kommentar(er)

0 kommentar(er)